Overview

Environmental protection is an important value at Hiray. That’s why we have built our own waste-water treatment plant. Our on-site wastewater treatment plant currently has a capacity of 80,000 gallons per day (300 m3/day) with real-time online monitoring. On full build-out, the plant will be able to handle 343,000 gallons per day (1,300 m3/day).

Wastewater effluent is continuously monitored, and data is sent wirelessly to local regulatory agencies to ensure it meets the following standards:

| Hiray Treatment Effluent | |

|---|---|

| Chemical Oxygen Demand (COD) | <657 mg/L |

| Ammoniacal Nitrogen | <114 mg/L |

| Phosphorous | <1.56 mg/L |

| Suspended Solids | <150 mg/L |

| pH | 6-9 |

After leaving our facility, the waste stream is further treated by the Sustainable Chemistry Industrial Park’s treatment facility and meets the following standards before being returned to the environment.

| SCIP Treatment Effluent | |

|---|---|

| Chemical Oxygen Demand (COD) | <50 mg/L |

| Ammoniacal Nitrogen | <5 mg/L |

| Phosphorous | <0.5 mg/L |

| Suspended Solids | <10 mg/L |

Pre-Treatment

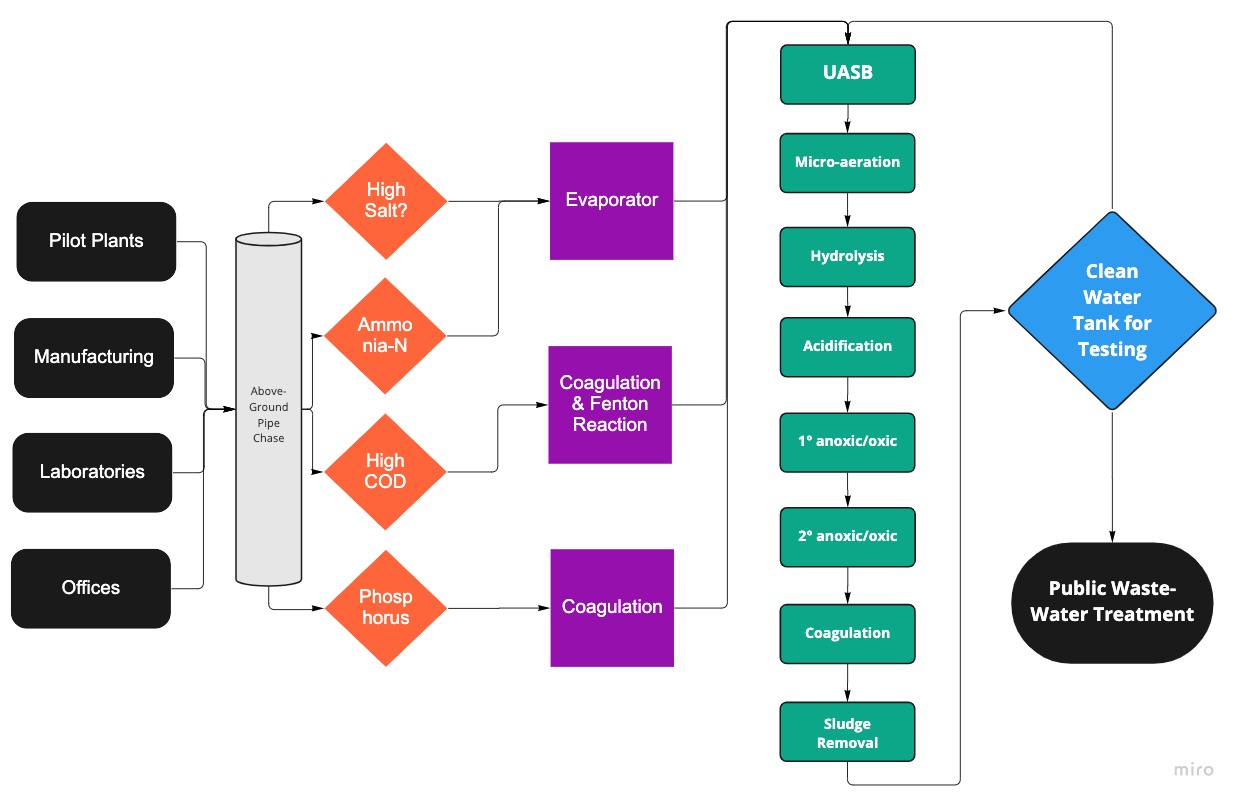

Liquid waste streams from the laboratory building, the pilot plant and production facility flow to our on-site treatment plant through above-ground pipes, which eliminate the possibility of hidden leaks contaminating our soil.

Liquid streams arrive at the treatment plant and enter the pre-treatment stage. In pre-treatment, streams with a high salt concentration or high ammoniacal nitrogen are processed in an evaporator. Domestic wastewater (water from i.e., from the kitchen, sinks, etc.) is pH-adjusted. Phosphorous-containing streams go into a designated tank for coagulation with polyaluminum chloride (PAC) and polyacrylamide (PAM). Waste streams with high chemical oxygen demand (COD) are also treated with PAC and PAM for coagulation, followed by processing in a Fenton reaction vessel where refractory and toxic organic pollutants are catalytically decomposed.

Biological Processing

After pre-treatment, the liquid waste is collected in one of two 600 cubic meter tanks for upflow anaerobic sludge blanket (UASB) processing. In UASB processing, wastewater flows upwards through the blanket and contaminants are degraded by the anaerobic microorganisms. The upward flow, combined with the settling action of gravity, suspends the flocculated sludge blanket.

The UASB effluent undergoes microaeration, precipitation, and hydrolysis acidification before entering primary and secondary anoxic/oxic treatment for biological phosphorous removal.

A final coagulation stage and sludge removal yield a stream of water that is pumped through above-ground pipes to the Sustainable Chemistry Industrial Park (SCIP) wastewater treatment facility, which is located directly across the street from our facility.